Contact down force is one of the most important factors in achieving a properly crimped pMDI canister. This precision device measures the contact down force in deka Newtons (daN) applied to the valve during the crimping operation.

· MDI direct placement transducer

· 0 to 200 daN Digital Readout

· RS232 Computer Interface

Contact down force is one of the most important factors in achieving a properly crimped pMDI canister. This precision device measures the contact down force in deka Newtons (daN) applied to the valve during the crimping operation.

· MDI direct placement transducer

· 0 to 200 daN Digital Readout

· RS232 Computer Interface

Precision ground gages to quickly and accurately verify that the crimp diameter is within specified limits. Made from hardened A4 tool steel to last for many years of service.

· Sets available for major valve manufactures

· Custom sizes available

· Metric sizes only

Precision ground gages to quickly and accurately verify that the crimp diameter is within specified limits. Made from hardened A4 tool steel to last for many years of service.

· Sets available for major valve manufactures

· Custom sizes available

· Metric sizes only

Designed specifically for pMDI use where the crimp Height is measured from the valve shoulder to the point in which the diameter of the crimped valve = 19.0 mm.

· Crimp height reading +/- 0.01mm

· Digital Readout

· RS232 Interface optional

Designed specifically for pMDI use where the crimp Height is measured from the valve shoulder to the point in which the diameter of the crimped valve = 19.0 mm.

· Crimp height reading +/- 0.01mm

· Digital Readout

· RS232 Interface optional

Determine pMDI leakage rate quickly and reliably with this rapid decompression chamber.

Determine pMDI leakage rate quickly and reliably with this rapid decompression chamber.

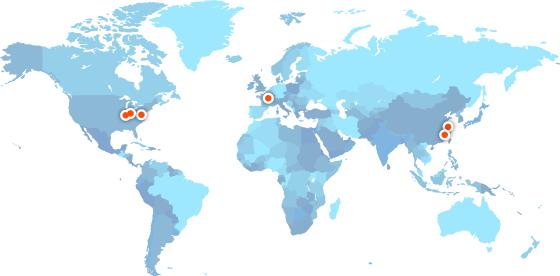

Spanish

Spanish Chinese

Chinese English

English