Anodized aluminum has been widely used for medical devices such as insulin injection pens, dental implants, surgical instruments and implants. The exacting part to part consistency achieved with our unique anodizing system cannot be obtained with conventional hoist line systems. A consistent uniform 6 to 12 µm anodic film thicknesses can be provided to meet your demanding application. The tight color control needed to meet the medical device industry recognition standards is a specialty of Anomatic.

Anodized medical device characteristics

· Smooth, hard, corrosion-resistant finish

· Satisfy functional, recognition and appearance requirements

Why Anomatic

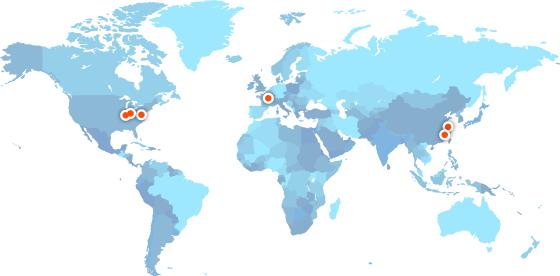

Headquartered in New Albany, Ohio (USA), Anomatic is the world’s leading supplier of anodized aluminum solutions and offers:

· U.S. and Asia based manufacturing

· State-of-the-art facilities

· Unmatched capacity at 2.5 billion units annually

· cGMP compliant, ISO 14001 and ISO 9001 certified

· Advanced surface treatment options

· Unrivaled lead times

Spanish

Spanish Chinese

Chinese English

English